J!m

Veteran and General Yakker

I know some of you guys find this stuff interesting, so I’m going to collect the pictures n stuff here.

First up: the arrival.

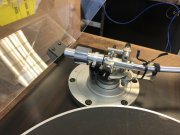

Very well packed with no “new” damage apparent. Platter was removed, as was the headshell and counterweight. Nice pack job.

It was supposed to be in its original box, which upset me, but then I noticed something:

I as not supposed to be getting an arm. Trading a ~$750 arm for an empty cardboard box seemed like a reasonable trade to me.

First up: the arrival.

Very well packed with no “new” damage apparent. Platter was removed, as was the headshell and counterweight. Nice pack job.

It was supposed to be in its original box, which upset me, but then I noticed something:

I as not supposed to be getting an arm. Trading a ~$750 arm for an empty cardboard box seemed like a reasonable trade to me.