J!m

Veteran and General Yakker

Got me some RCA wye connectors so I could add the speakers from the Bradford system downstairs!

Rockin’!

Rockin’!

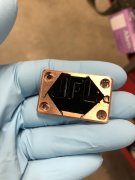

How are you planning on removing the excess paint?So, the original aluminum face plate had two knobs on it originally (volume and selector). I'm only using one, but there is a large counterbore like the one I am using, under the copper. So I made a "washer" to make up the difference and keep the bushing aligned etc.

View attachment 60498View attachment 60499

Then I got the engraving filled with appliance epoxy spray paint. It's great stuff but takes a week to fully cure (or be topcoated). So, I think I may have to wait the week because the copper will tarnish within a week, and then not look as nice. But I'll probably work on polishing the chamfers in the meantime.

View attachment 60500View attachment 60501View attachment 60502View attachment 60503

Duh…I think I missed the part where you were repurposing an existing faceplate, makes sense now. (In my defense, I was blinded by the the bling).Sand paper.