Peter S

Journeyman

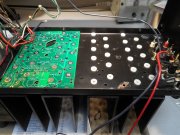

While I'm on the topic of dumb questions, I have found the WO back plane pcb's to fit snugly in the steel Clair Bros chassis. The T 03 screw holes in the chassis will all have to be cleared with a 15/ 64" drill. The nylon shoulder washers at the upper and lower most locations will need a 'flat' removed from the larger diameter shoulder, to clear the top and bottom of the chassis. Has anyone had to do this or is this a sign of trouble coming?

Thanks, Peter in Canada

Thanks, Peter in Canada