Finally my first documented audio refurbishment. I have had little time to post so there are a few days of photos that I’ll post showing my path and issues I came across while updating this beautiful piece of equipment. Thanks Lee for all your help and the nice face plate upgrade you scored.

Some photos of the 3300 II before upgrades. Sorry no photos with the top or bottom on as I couldn't help myself - had to pull the lids minutes after opening the box when I received the 3300 II.

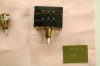

If you look closely at the trace side of the board you will see flux residue that was not cleaned from the orginal build. It is a good idea while you're in there to clean up stuff like this.

Some photos of the 3300 II before upgrades. Sorry no photos with the top or bottom on as I couldn't help myself - had to pull the lids minutes after opening the box when I received the 3300 II.

If you look closely at the trace side of the board you will see flux residue that was not cleaned from the orginal build. It is a good idea while you're in there to clean up stuff like this.

Attachments

-

2.1 MB Views: 300

-

2.4 MB Views: 220

-

2.3 MB Views: 193

-

2.2 MB Views: 198

-

2.3 MB Views: 211

-

2.4 MB Views: 174