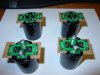

The caps are assembled but the fit in the original PL400 clamps is not to my liking. I think I will explore some 40mm clamps and maybe I can reuse two out of three original mounting holes.

Thoughts from the safety gallery?

[attachment=3:lbmkcr7r]Caps 1.jpg[/attachment:lbmkcr7r]

BTW, this is how to assemble these, at least my method. Solder the boards to the top cap with a piece of manila folder in between the cap and the circuit board (Joe told me about that little trick) to get the proper clearance.

Like this:

[attachment=2:lbmkcr7r]Cap Spacers.jpg[/attachment:lbmkcr7r]

Once the boards are soldered in place, cut the support wire to the length of the caps plus 1/2". Then solder the wire in place on the top cap like so:

[attachment=1:lbmkcr7r]Cap Assembly.jpg[/attachment:lbmkcr7r]

Once the wires are soldered on the top cap, insert two or three pieces of manila folder between the bottom of the top cap and the bottom circuit board to prevent the sharp cut terminals from gouging the bottom of the cap. I turned the assembly over and soldered the wires from the bottom of the lower circuit board.

Be sure you have the insulating sleeve tubing on or you will have to start over. Also make sure the caps are aligned + to + and - to - or you will be sad.

I added a bypass cap to the upper assembly but make sure the wires don't stick out the bottom.

[attachment=0:lbmkcr7r]Final Cap Assembly.jpg[/attachment:lbmkcr7r]

16,400 uF of capacitor storage on each side for a total of 32,800 uF for the amp. Joe, I like it. I thought the wires were pulled tight to hold the caps together. Now I see the rigidity of the larger gauge (16 GA) is what holds the caps in position relative to each other.