- Joined

- Jan 14, 2011

- Messages

- 75,551

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

Due to the lower compression and combustion temps no doubt...

Due to the lower compression and combustion temps no doubt...

Inside joke there LeeI may have missed a post...did someone say this earlier???

The part number might be a mystery forever, but if it runs it runsThanks, Robert. I don't believe that's a Ford service # for the piston. The mystery deepens.

Nando.

Are the 3.8 head gaskets designed with some specific and non-obvious orientation? The 302 gaskets are. They fit either way, but if you put them on backwards it blocks a coolant passage and you have overheating problems.

This is a sideways motor so the markings on the gaskets mean absolutely nothing as to which bank is left or right. I just guestimated that they go on this way. I should have looked at the orientation when I took off the original gaskets.

This is a sideways motor so the markings on the gaskets mean absolutely nothing as to which bank is left or right. I just guestimated that they go on this way. I should have looked at the orientation when I took off the original gaskets.

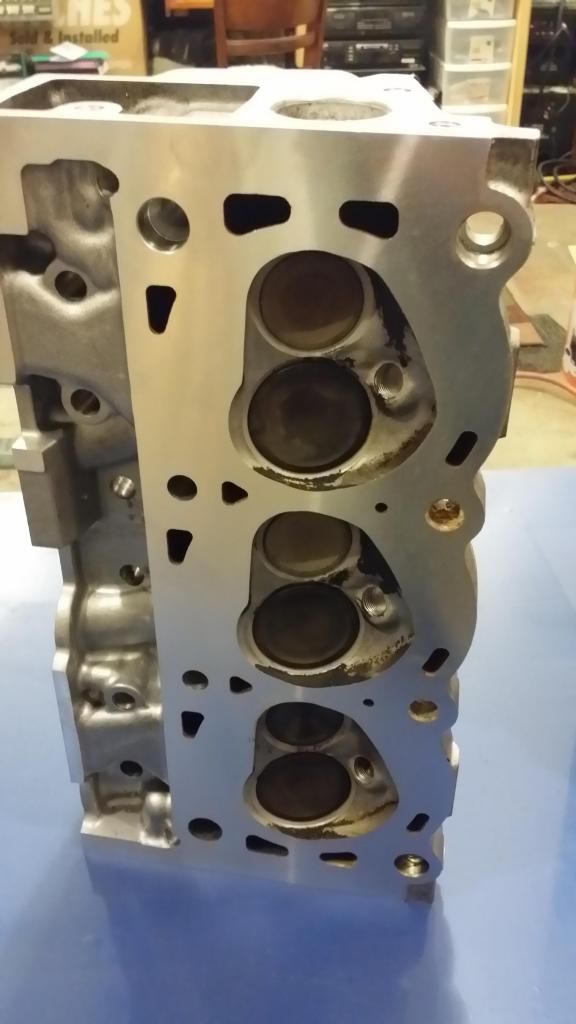

Notice the coolant passages on the left side versus all the rest..... This one cylinder is going to run considerably hotter than the others as some of the passages are blocked off completely.

Both banks are the same as far as the gaskets are concerned. Another mystery to me as to why these coolant passages are blocked offThis is a sideways motor so the markings on the gaskets mean absolutely nothing as to which bank is left or right. I just guestimated that they go on this way. I should have looked at the orientation when I took off the original gaskets.

Is this motor back together?

Spent all day getting the Ford back together. Disable the ignition pack cranked it till the oil light went out plugged it back in fired right up. No leaks no misfires runs strong. All is well. no all I gotta do is drain the water and put regular coolant back in. Did not want to waste the money in case it started leaking, so I save the coolant for last. In 300 miles I will change out the filter and oil again , and call the job complete.

Spent all day getting the Ford back together. Disable the ignition pack cranked it till the oil light went out plugged it back in fired right up. No leaks no misfires runs strong. All is well. no all I gotta do is drain the water and put regular coolant back in. Did not want to waste the money in case it started leaking, so I save the coolant for last. In 300 miles I will change out the filter and oil again , and call the job complete.