MarkWComer

Veteran and General Yakker

- Joined

- Nov 1, 2014

- Messages

- 3,520

- Location

- Gaston, SC

- Tagline

- Victim of the record bug since age five

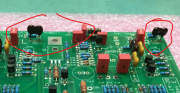

You elevated a few caps above the board. Not wrong, but unusual. I assume for heat dissipation? I elevated the high wattage resistors a bit on my builds for this reason because of the obvious heat damage on the original control circuits. This may be moot, did it regardless. I think I did this on the emitter resistors as well, don’t recall precisely.