Alright, So my Father has Retired as of Dec 23rd. In his 70's now, the man has worked way longer than he should have. But work-aholics run in the family, I get it. Now he is ready to turn his attention BACK to speakers and amps and Vintage gear. I am continuing this thread where it left off because that's basically where HE left off. -Still uncertain about the PL gear and "Carver this" and Carver that". "They sound like Tube amps". But the man doesn't want to pay money to get a vintage piece of equipment to "Try Something Out" then ya can't send it back. So he's stuck only reading internet opinion pieces of the gear.

My Hope here, is to put this continuing saga to BED. Lord knows it's been going on for over a decade now. It's time to WHITE OAK this beyatch!

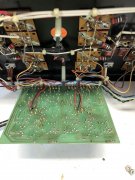

And what better opportunity than now, as fate would have put it; one of his four PL400's blew up and was blowing channel fuses. I decided I was going to overhaul it for him. I mean I can't break it anymore than it's already broken? CAN I?......

So two weeks ago I got all the W.O. parts I could think of and started looking my project in the face. He's had these things for 40 years and they have never been to an audio shop. He at one point replaced them sometime in the 90's with an Audio Research SP3 Pre-amp and an Audio Research D-70 something? Hell I can't remember. But in the late 2000's, he sold it off because he said it was getting too ridiculously expensive to replace the vacuum tubes. $800 per tube or something nutz! Back to the 400's he went. And since then he never really got over that "Tube Sound".

We tried introducing here in this thread, Jerry's amp, but in 2014, I think we only had the driver board RevB and the bulk caps at our disposal. He didn't really hear the difference vs cost-to-build thing. So back it went. Fast forward to TODAY and man things have changed. I will be updating this thread as I go. It's time to treat the man who raised me for half a century to a fine reward. His own WOPL. He never liked the sound of the PL700B's. Maaaybe he could tell but a slight difference in that the PL400 wasn't as "harsh" on the high end. Like Mark said somewhere else on this forum, It's getting to the point at this age where I can't tell the difference between the two. The golden ears in his golden years are starting to fade, but his listening tastes have become finer and even more specific. I hope this project helps him see that once you go WOPL, you never go back.

I still am not that confidant in my abilities, but I feel I have a better handle on it than I did 8 years ago. A lot of the tech-spec talk is over my head. I fully admit it. This will either be a great project or a WOPL Sniffer-type Mushroom Cloud! I am as Green at this as Joes Boards! So bear with me guys. I'll need your help.

and has a more refined sound

and has a more refined sound and has a more refined sound

and has a more refined sound