RoHS = The Return of an Old Enemy to Electronic Reliability

If you've ever decided on a plan of attack with the old saw, "If it ain't Broke, Don't Fix It", then you will appreciate the havoc that well-intentioned yet non-technical types have inflicted on those who are responsible for designing/manufacturing complex systems that need to be reliable in order to support our quality of life.

From ATMs to cell phone towers to traffic lights to nuclear plants to ambulances, planes, trains, & automobiles, hospitals, etc., high reliability electronic systems are more than just a feel-good statement or 1st-world luxury.

****

But in the early 2000s, the EU responded to the threat of pollution from discarded electronics by passing the RoHS Directive. (

Restriction

of

Hazardous

Substances) Starting in 2006, if you wanted to sell your product into the EU, then you needed to prove that your product was clean enough to wear the following:

Here's the

list of banned chemicals. NOTE: How many total grams of solder is used in a typical automotive radio, computer, and/or the factory wiring harness? (~28 grams = 1 ounce) But what about the 30-50 lbs of lead in a conventional 12-volt battery? Oh yeah, car batteries are

excluded from the ROHS Directive...they are covered by separate recycling laws. (!)

Don't get me wrong, if I can no longer buy a chrome bumper on my new car in order to protect the environment, I'm OK with that...since that doesn't affect the overall reliability of the vehicle. But the lead-free solder edict has no doubt affected anyone reading this, even if you weren't aware of exactly

why your electronics widget suddenly packed it in for seemingly no reason at all.

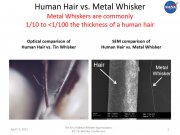

Since pictures are worth a 1000 words, here's a few photos to introduce some of you to the lead-free 'tin-whisker' phenomenon:

(Taken from the

excellent NASA reliability article on metal whiskers that spontaneously grow from pure metals - well worth a read.)

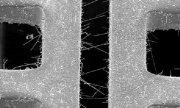

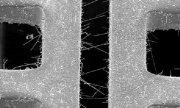

Obviously, large scale point-to-point wiring in a Marshall amp may rarely, if ever, suffer from tin whisker-induced shorts. On the other hand, the closer/smaller/finer the electronics layout, the more that these tiny

conductive threads can create unintended interconnects between circuit board features:

Micro-photograph showing tin whiskers bridging the spaces between circuits.

If the NASA article just whetted your appetite for more, this link to an

IBM white paper on the history of the tin whisker problem (with emphasis on research by Bell Labs back in the day) will give you the stuff you need in order to be the life of the party the next time you are hanging out with your geek posse. :0)

There's plenty more where that came from, but instead I'll just add a couple more thumbnails for your viewing pleasure:

SMD devices growing tin whiskers from the lead-free solder.

NOTE: The authors mentioned that these tin whiskers can be easily overlooked during a visual inspection...especially if you don't own a stereoscopic inspection microscope. Interestingly, depending upon the amount of current available in the circuit, the tin whisker can either create a new recurring intermittent (low current) all the way to a self-clearing plasma failure involving hundreds of amps. Well, geek -- Do You Feel Lucky? :0)

Once NASA became woke about metal whiskers, they did their own deep dive on the (then 18-year-old) Space Shuttle fleet, and came away with these photos. And if you read their report, even on the ground it seems that they traced a FOD failure inside a server to the conductive whiskers located on the underside of the raised-floor tiles in the computer room becoming dislodged & blown around in the cooling air until it ended up inside the computer & causing a short between logically-unrelated circuits.. (!)

****

I think this is a good place to stop. Now when you read about how some industries (like Aerospace) continue to fight for the use of leaded solder in electronics it will make more sense. And if you are repairing Mil-Spec gear then leaded solder is still specified in the Technical Orders.

And when the gurus in this forum recommend that you avoid lead-free solder, it's not just because of shiny solder connection vanity or trying to help you avoid throwing excessive heat into the leads of your spendy electronic components, lowering their useful lifespan in the process.

Lead-free solder is just bad juju. What can I say? Sometimes the road to unreliable electronics is paved with good intentions.

:0)

Hope this provided a little insight into the real-world reliability concerns from using sub-optimal solder in our treasured toys.

3D

EDIT: Following the lead of the European Union, California, NY, and like-minded states adopted similar RoHS laws. Nothing at the Federal level as far as I could figure out, but this isn't an 'us vs them' issue -- this even includes China. If you are thinking about stocking up on "the good stuff" now is a good time, for as we have seen, a lack of knowledge does not deter some from deciding to ban what we need in order to protect us from ourselves...