My .02 worth.

Capacitors are interesting passive creatures. They can block direct current (DC) and allow alternating current (AC) to pass, but we also use them in our DC power supplies to filter out (block) the AC and let the DC pass. They even store DC electricity like a battery! Weird, huh?

The two main categories are electrolytic and everything else, the difference is the construction but the construction has come to determine the use.

The electrolytic caps (most often polarized) in our amplifiers are used for two purposes. 1) Power conditioning, used to shunt away power line hum before it gets into the signal circuitry. The capacitors act as a local reserve for the DC power source, and bypass AC currents from the power supply. 2) Coupling and suppression. In

coupling, capacitors pass AC but block DC signals (when charged up to the applied DC voltage), they separate the AC and DC components of a signal. This is

AC coupling or "capacitive coupling". A high capacitance is used but the value is not critical, but the reactance is small at the frequencies used. In

uncoupling, a capacitor used to protect one part of a circuit from the effect of another, for instance to suppress noise or transients. Noise is shunted through the capacitor. Uncoupling capacitors are used between the power supply and ground. These are also called bypass capacitors, used to bypass the power supply or other high impedance component of a circuit. In suppression, look for electrolytic caps in industrial environments.

Other electrolytic capacitors are tantalum and niobium capacitors. The tantalum capacitor consists of a pellet of porous tantalum metal as an anode, covered by an insulating oxide layer that forms the dielectric, surrounded by liquid or solid electrolyte as a cathode. Tantalum electrolytic capacitors have two electrical functions. For timers or similar applications, tantalum capacitors are used as a storage component to store electrical energy. But for smoothing, bypassing, or decoupling applications, the capacitors work as AC resistors to filter undesired AC components from voltage circuits. Niobium capacitors are similar, a polarized capacitor whose anode (+) is made of passivated niobium metal or niobium monoxide on which an insulating niobium pentoxide layer acts as the dielectric of the niobium capacitor. A solid electrolyte on the surface of the oxide layer serves as the cathode (-) of the capacitor and a price rise for tantalum in 2000/2001 encouraged the development of niobium electrolytic capacitors.

The everything else category refers to film, mica, ceramic and everything except the electrolytic. These capacitors are not polarized and are plentiful in audio circuits as low voltage or low capacitance value bypass, filtering, and signal conditioning. These smaller value capacitors can be combined with resistors and inductors to form RC and LC networks. One use is the Zobel Network (.1 uF Cap and dual 5 Ohm 2W Resistors) on the speaker binding posts of our Phase Linear amplifiers. This network bypasses low frequency voltage coming back into the amplifier, generated from the coil of the woofer speaker.

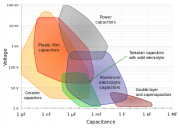

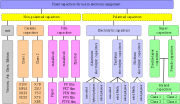

These types of caps have their own ideal use.

Film caps can be film/foil or metalized film, they used to have an oiled paper dielectric but today the dielectric is polycarbonate, polypropylene, polyester (Mylar), polystyrene, or Teflon . They are wound with the edges of the two metallic windings in contact with the electrodes on both ends of the windings. This contact keeps all current paths to the entire electrode very short. The setup behaves like a large number of individual capacitors connected in parallel, thus reducing the internal losses (ESR) and the parasitic inductance (ESL).

Mica caps are made with thin (.025mm) sheets of muscovite mica coated with metal on both sides. They are used in high frequency applications due to low resistive and inductive losses. They are also extremely electrically and mechanically stable and can tolerate high heat.

Ceramic caps are the most common capacitors made (1000 Billion per year) due to their surface mounting (SMD) capability. These are the Multi-Layer Chip Capacitor (MLCC) and also the common disc capacitors. They are not polarized, which means that they may be safely connected to an AC source. Ceramic capacitors have a great frequency response due to low parasitic effects such as resistance or inductance.

The remaining group in the everything else category includes the miscellaneous category known by their dielectric: air, vacuum, glass, and silicone. They are uncommon in audio circuits.

I will not mention supercapacitors, because they are just to far out.

Some graphics to assist in the understanding...

View attachment 50536

Adapted from Wikipedia, with numerous edits for clarity.