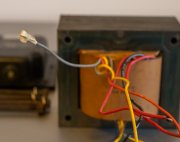

Before ordering the full Kit, I made some cleaning and finally checked the transformer. It looks like, but I may be wrong, that it had a little hot moment, if you look at the pictures. I tested it, looks like it's ok but without any load , and does not smell. Wondering what to do...

Btw, there is a grey wire not connected, should it be the midddle point of the 12V AC ? Output is 2 x 61V for 236V input

Btw, there is a grey wire not connected, should it be the midddle point of the 12V AC ? Output is 2 x 61V for 236V input

Attachments

-

433.2 KB Views: 28

-

417.6 KB Views: 29

-

396.4 KB Views: 28

-

359.8 KB Views: 27

-

472.2 KB Views: 25

-

328.9 KB Views: 27

-

466.8 KB Views: 27