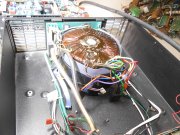

Hi Folks, my modified Crest CA-18 went out with a bang. Three or four almost gunshot blasts, I thought some electrolytics exploded. My fatal mistake may have been to install slower fans to reduce noise as the rack is located in the listening room. There have been rare occasions when the amp's full power has been demanded but I thought I could get away with quieter fans for home theatre use.

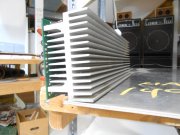

Attachments

-

3.2 MB Views: 54

-

3.1 MB Views: 56