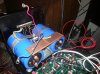

And the other trick is shown here Jer. Skipping the bottom slot allows you to install the pre-driver transistors for initial bring up while still having the heat sinks securely in place. You MUST use nylon washers to do that bring up trick. Otherwise you will just blow your rail fuses if you use metal washers.

View attachment 12704

Now he tells me