rollcentre

New Around These Parts

- Joined

- Mar 22, 2021

- Messages

- 48

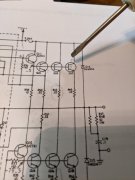

The quasi comp versions has a parallel path that likes to oscillate if the RCA 410's are not used in the negative column. I found out the hard way. Credit to Joe on that one.

Roll, when you replace the board, send me the old one. I'll do a failure analysis and try to determine if a board failure caused your amp to blow. When you install the new board pay particular attention to the bias transistor on the failed channel. All your work will be for naught if there is an issue there. I once had a 700B that I put all new outputs in and the bias transistor failed. Took out all of the new outputs in that channel.

I will indeed send you the old board. I'd love know what you find.

As for the bias transistors, I will check them out. That would really suck to pop all of the output transistors. They are almost up to 9 bucks a piece on mouser. I grabbed a few from Joe to replace these and have a couple backups.