vince666

Chief Journeyman

Hi guys,

finally my own project on one of my AIWA AD-F880 , started a long time ago and where I've applied a long series of modifications, is quite ready!

These first few post are just a teaser... as soon as I gather all the details, schematics, ect, I will add them here in this thread.

At first, the deck had all the mods by Alex/ANT applied, to make it an AIWA AD-F880M (new op-amps on PB and REC amps, a few capacitors, a couple resistors, a couple diodes).

Also, this deck had quite a bit worn heads, which I've lapped and got improved but I wasn't too satisfied and was hoping to replace them with some new heads.

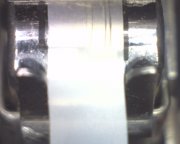

So, a while ago, I've found some nice "AX" amorphous heads (an original spare for some 80's TOTL Technics models) which were missing the fork guide and the guide was intended to stay at left/REC side... So, I've managed to take the guide from a broken head and put it on the right/PB side, as needed to fit and work in the AIWA deck. (not an easy work! I had to design and DIY a tool to properly align the guide and also modify the mounting plate as the screw holes resulted to be skewed horizontally and the head couldn't stay at the proper place).

Then, I've fixed what I consider a very stupid designing error about the way they attached the mech block to the chassis which made the deck quite unreliable.

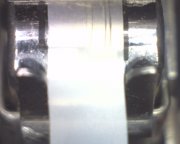

The problem is that, originally (as you can see in the below picture), the mech block was attached with the two upper corner screws directly at front panel and then the two lower corners screws were attached to some L-shaped wings to a base plate with the AMTS spring and then the base plate was screwed to the base chassis.

This (very stupid) situation caused a torque stress to the main mech plate (and then quite a lot of W&F towards the end of cassette sides) , due mostly to a couple reasons: the quite strong AMTS spring which pushes the cassette against the mechanism when you close the cassette door, through the rubber/metal plate they named AMTS, and also the point that the mech is attached a bit on the front panel and a bit to the base chassis which aren't so solidly secured themselves, then i.e. you put a deck stacked on the AIWA and it also stresses the mech the same way as the AMTS plate/spring!

For a few years, I was forced to regularly open the deck and bend back a bit those "L shaped" wings but the solution was short lived and I had to repeat it regularly.

At some point, I tried to find a definitive solution to this stupid designing mistake: attaching the mech block to the front panel only!

Then, I've cut those L-shaped wings from the base AMTS support (which is still needed to stay in the deck because of the AMTS spring) and noticed the lower corner (plastic) mounting posts at front panel were just there but they were a bit shorter, to make some room for that stupid L-shaped thing.

So, i've found a way to make those posts longer, to reach the lower corners of the mech block and re-attached the mech to the front panel only!

Also added some ground wires because, in original shape, the mech attached to the base chassis got the gnd from there.

Problem solved!

Then, of course, I've applied a few mods to the electronics to make the new amorphous heads work properly (details later).

And, since I was there, I also replaced all the electolytic capacitors... and, while doing that, I've found out that on this model (I own two AD-F880 and both have the same factory error!) there is one polarized electrolityc capacitor which is reverse biased by about 7 volts (!!!) due to a wrong print on the PCB...

It happens that this capacitor is there to filter a -7 VDC (minus seven) line and they put the negative of the cap to gnd and the positive of the cap to the -7 VDC.

But, being a negative supply, you have to put the positive of the cap to the gnd and the negative to the (negative) supply, otherwise it's reverse biased!

Of course, I've put the replacement capacitor the proper way.

will continue on next post...

finally my own project on one of my AIWA AD-F880 , started a long time ago and where I've applied a long series of modifications, is quite ready!

These first few post are just a teaser... as soon as I gather all the details, schematics, ect, I will add them here in this thread.

At first, the deck had all the mods by Alex/ANT applied, to make it an AIWA AD-F880M (new op-amps on PB and REC amps, a few capacitors, a couple resistors, a couple diodes).

Also, this deck had quite a bit worn heads, which I've lapped and got improved but I wasn't too satisfied and was hoping to replace them with some new heads.

So, a while ago, I've found some nice "AX" amorphous heads (an original spare for some 80's TOTL Technics models) which were missing the fork guide and the guide was intended to stay at left/REC side... So, I've managed to take the guide from a broken head and put it on the right/PB side, as needed to fit and work in the AIWA deck. (not an easy work! I had to design and DIY a tool to properly align the guide and also modify the mounting plate as the screw holes resulted to be skewed horizontally and the head couldn't stay at the proper place).

Then, I've fixed what I consider a very stupid designing error about the way they attached the mech block to the chassis which made the deck quite unreliable.

The problem is that, originally (as you can see in the below picture), the mech block was attached with the two upper corner screws directly at front panel and then the two lower corners screws were attached to some L-shaped wings to a base plate with the AMTS spring and then the base plate was screwed to the base chassis.

This (very stupid) situation caused a torque stress to the main mech plate (and then quite a lot of W&F towards the end of cassette sides) , due mostly to a couple reasons: the quite strong AMTS spring which pushes the cassette against the mechanism when you close the cassette door, through the rubber/metal plate they named AMTS, and also the point that the mech is attached a bit on the front panel and a bit to the base chassis which aren't so solidly secured themselves, then i.e. you put a deck stacked on the AIWA and it also stresses the mech the same way as the AMTS plate/spring!

For a few years, I was forced to regularly open the deck and bend back a bit those "L shaped" wings but the solution was short lived and I had to repeat it regularly.

At some point, I tried to find a definitive solution to this stupid designing mistake: attaching the mech block to the front panel only!

Then, I've cut those L-shaped wings from the base AMTS support (which is still needed to stay in the deck because of the AMTS spring) and noticed the lower corner (plastic) mounting posts at front panel were just there but they were a bit shorter, to make some room for that stupid L-shaped thing.

So, i've found a way to make those posts longer, to reach the lower corners of the mech block and re-attached the mech to the front panel only!

Also added some ground wires because, in original shape, the mech attached to the base chassis got the gnd from there.

Problem solved!

Then, of course, I've applied a few mods to the electronics to make the new amorphous heads work properly (details later).

And, since I was there, I also replaced all the electolytic capacitors... and, while doing that, I've found out that on this model (I own two AD-F880 and both have the same factory error!) there is one polarized electrolityc capacitor which is reverse biased by about 7 volts (!!!) due to a wrong print on the PCB...

It happens that this capacitor is there to filter a -7 VDC (minus seven) line and they put the negative of the cap to gnd and the positive of the cap to the -7 VDC.

But, being a negative supply, you have to put the positive of the cap to the gnd and the negative to the (negative) supply, otherwise it's reverse biased!

Of course, I've put the replacement capacitor the proper way.

will continue on next post...