62vauxhall

Veteran and General Yakker

- Joined

- May 14, 2014

- Messages

- 2,365

- Location

- Southwest Kootenays BC

- Tagline

- No such things as bad days, just bad moments

What voltage should be present at the Base pad of Q1?

The MJE15032G I recently installed there failed. After multiple 2SD288's failed several years ago because of grounded Collectors, I thought this latest transistor without being shorted was the answer.

As per the service manual, 23 volts was obtained at tab #36 so I thought things were rosy. A couple of days later, when I measured again, there were a few hundred millivolts and the new Q1 was too hot to handle.

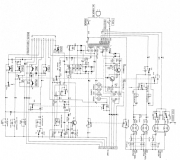

I removed the MJE15032G and checked it with a DMM and it's a goner. That made me wonder what voltage it was seeing and I measured 41 volts and it's Base pad. The schematic does not help as I've not seen any voltages printed on it. I thought the most I'd measure was 23/34 volts.

The MJE15032G I recently installed there failed. After multiple 2SD288's failed several years ago because of grounded Collectors, I thought this latest transistor without being shorted was the answer.

As per the service manual, 23 volts was obtained at tab #36 so I thought things were rosy. A couple of days later, when I measured again, there were a few hundred millivolts and the new Q1 was too hot to handle.

I removed the MJE15032G and checked it with a DMM and it's a goner. That made me wonder what voltage it was seeing and I measured 41 volts and it's Base pad. The schematic does not help as I've not seen any voltages printed on it. I thought the most I'd measure was 23/34 volts.