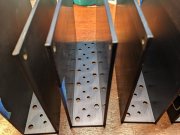

Starting mock up. I want to use a 20 amp IEC socket and cord. It should just fit in the accessory fan socket area. It's going to be tight but doable. This will be a full WOPL including Joe's awesome meters, using the original heavy steel chassis. All parts are at hand.

The part # for the socket is "Interpower 83030410". Most important is the solder tabs readily accept the 14 AWG wire. The cord was used for Dell 1000 watt desktop computer power supplies, and should be available new from Mouser or Digikey.

This is going to be a long, slow build, but I'll try to document it for the new guys.

The part # for the socket is "Interpower 83030410". Most important is the solder tabs readily accept the 14 AWG wire. The cord was used for Dell 1000 watt desktop computer power supplies, and should be available new from Mouser or Digikey.

This is going to be a long, slow build, but I'll try to document it for the new guys.