- Joined

- Jan 14, 2011

- Messages

- 75,891

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

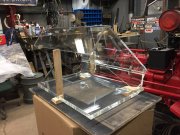

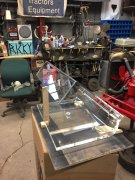

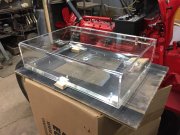

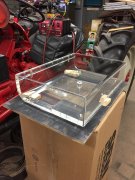

That is a beautiful lid...

Pops said the pics don’t do it justice! The rear mounting holes are drilled and it was temporarily bolted to the hinge for correct alignment. I’m going to countersink the holes at my shop to the correct depth for the screws I use and obviously have to make the grab handle/spot buttons and prop, rod but that won’t take long once I get at it!That is a beautiful lid...

ackshually... I'm a bit out of my usual zone as I haven't worked with acrylic at all really. I talked to the fabricator and we discussed drill bits, basically he suggested sharpening them to a 90* point and using a hand stone to flatten the edge (remove rake angle). Similar to drilling brass, removing the rake angle prevents the bit digging in on its own. Probably use a single flute countersink to prevent chatter and aggressive cutting also. I really don't want to crack or scratch itObviously......a machinist in his own envirinment should be able to make that happen...

Not sure I want to give up my... “purity” to McMaster Carr over 5 tiny bolts... the shipping would be crazy! Pops can get them from fastenal through his work or just walk in. I don’t really have anywhere close to me for that stuff. Most regular hardware, even stainless is pretty easy because of the fishermen, but 8-32 Allen head countersunk stainless... nah.McMaster-Carr is your new best friend.

All sorts of hardware and other bits for fun projects.

Might get home early to work on stereo stuff... we holed the ship this evening. Bumped into a bridge abutment...

Need to hear more about how you "bumped into a bridge abutment." Loss of steering? Drunken crew? Bridge abutment suddenly turned in front of you? Don't leave us hanging...Might get home early to work on stereo stuff... we holed the ship this evening. Bumped into a bridge abutment...