girbob75

New Around These Parts

- Joined

- Feb 8, 2023

- Messages

- 17

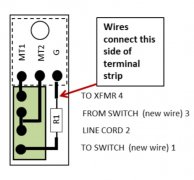

This thread has been a long time coming. I started this journey back in 2023 purchasing a Phase Linear 400 in very nice shape with two issues. One of the gauge bezels was missing and there were two blown transistors. Thanks again Lee for all the parts and information, couldn't have gotten started without you. I rocked this thing for a few months and purchased a control board from Joe and built it my spare time. As time went on I started purchasing parts for a rebuild. It was then I blew a transistor by driving the amp a little too hard. POP! I realized that I wanted to do a full rebuild. I purchased the backplane boards from Joe sometime last year and just recently grabbed a new housing and the transistors. Thanks to this group and Joe's kits with instructions Linda Linda lives again. Reading everyone's rebuild questions really helped out a lot. I can't forget about Don. His dc protection board and triac switch are the parachute and safety net everyone appreciates in their builds. Everyone is working correctly at the correct voltages and bias but the transformer is buzzing more than before. I think I need to crank down the bolts or reposition the cover slightly I don't know. It looks like I'll be pulling the caps out in the next few weeks. I'll just listen to everything a little louder until then.