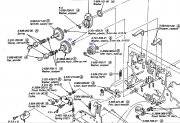

I see the brass drive stub contacting the tire.

Is there not a felt disc clutch with a spring somewhere in the mechanism that would permit proper tension and slippage?

The Phase Linear deck I'm working on has two felt clutches.

One clutch for fast F+R, and another clutch for play.

I can already see that I'll have potential issues with tape tension if the felt or springs are out of spec.

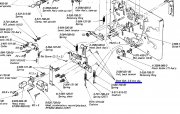

Is there not a felt disc clutch with a spring somewhere in the mechanism that would permit proper tension and slippage?

The Phase Linear deck I'm working on has two felt clutches.

One clutch for fast F+R, and another clutch for play.

I can already see that I'll have potential issues with tape tension if the felt or springs are out of spec.