I wanted to update you guys on where the project stands.

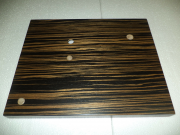

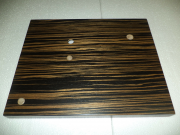

This is the new plinth I ordered. I have no idea if I will receive this *exact* one, or simply one veneered with the same species. We'll find out soon I guess. I think it looks nice. Modern, yet "classic" at the same time.

The base table is a black on black (logo decal/printing on the plinth is black on the black melamine laminate) Planar 3 with the smoked dust cover. (might need to polish that for it's new home..)

(image stolen from the web. I don't have my original papers or that cartridge, but it is for illustration porpoises only.)

To this, we add the following TangoSpinner bits:

ZIRCONIA HI-LUBE SUBPLATTER: Metal Subplatter with Silicone Decoupling Stages and Vesconite Hi-Lube terminal ending (normally supplied with a Zirconia bearing ball and a fancy silicone belt). Basically, it has a hi-tech plastic termination on the end of the stub. I don't yet know how this compares to the hi-tech plastic bearing balls I sourced, but should essentially do the same thing- isolate the spindle from any bearing noise, and with my new bearing, there isn't any noise to begin with. Maybe it will

absorb noise from elsewhere... Gus provided this "flagship" subplatter for the price of the BOTL model I had spec'd out.

Brass dual-belt pulley (fixed 33.33 RPM operation). He offered the brass for the price of the aluminum, so, why not? I don't personally see any operational benefit from the brass over aluminum in this location, but it certainly won't hurt performance. They use an internal quad-ring (an o-ring with a four-lobe cross section, if you're not familiar) and no set screw. No off center setting from the one sided push and no imbalance from the screw (but at that radius, it would be insignificant in the grand scheme). You can always go with an aluminum or brass set screw on your set-screw pulley if you like, to match density of your current set-screw pulley.

The major "bling" bit will be the Libertango Platter (black with polished/brushed aluminum perimeter ring)

This is what it would look like on the original plinth. This platter operates without any platter mat- record sits directly onto the Delrin. Some sell Delrin platter mats to achieve the same coupling- hopefully it's the right decision... (but I will be using the Michell VTA nut, if I choose to add a mat on there) And the aluminum perimiter increase inertia, which (should) reduce W&F significantly.

And last, but hopefully not least, nice adjustable feet. Currently I use old, obsolete business cards to shim the stock Rega feet and level the plinth. Welcome to the 20th century!

The nylon (black) bit gets screwed to the plinth, in the original locations (using original hardware). Then the aluminum cone threads onto the stub. Plenty of height adjustment. Tips are either Silicone (standard) or Urethane (upgrade?) Gus provided the Urethane version for the Silicone price.

That's cool, but, Gus also covered FedEx/DHL shipping! Basically, I received a discount from $545 to $420

The only remaining upgrade, which I may farm out, is to rewire the arm. If I do that, I will also put output jacks on the table, single-ended as well as balanced. I think there is a lot of value in running the line from the cartridge to the phono preamp as a balanced line, to take advantage of the noise rejection in this very low-level signal. (hey, that's why microphones are balanced!) I'll probably use either mini XLR jacks (as used on headphones these days), or Lemo B-series.

Once this is together, I will re-evaluate my drive belt situation. Currently I use the "type 2" belt, from my belt test kit. It has very stable speed- the most stable of the six materials I offer in the kit. That may change, going to two belts and all this other stuff being changed. It will be a completely different table. I hope it doesn't suck!

Stay tuned! I have all the parts for completing my first DAC, so I'm going to keep busy with that, while I wait on these parts and the SX-880 parts.