Other advice Gene, sell that PL200, the worst amp made by PL. The PL200 S2 was a solid performer but not the S1. The S1 looks to have been designed by their summer interns...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

phase linear 400

- Thread starter gene french

- Start date

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

i will gift it to one of my son in laws....and i do understand....

as soon as i recap the power supply caps...

thanks joe...

as soon as i recap the power supply caps...

thanks joe...

Good plan Gene, fingers crossed it does not end up back on your bench for repair in the future.i will gift it to one of my son in laws....and i do understand....

as soon as i recap the power supply caps...

thanks joe...

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

if it does....i will deal with it....i kinda enjoy....

lol,,,,

lol,,,,

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

I added Costa Rica to the sold to country list on the website in honor of Gene...even the trip of 1000 miles starts with the first step...

Gene, probably hasn't been mentioned, but many of the guys make a custom buss bar for between the caps. I find the original is adequate, so I use it. However, I drill extra holes for the extra ground wires. Two holes on either side of the slot, sized to each hold two 16 AWG wires. Then I steel wool it to make it shine, then clean with alcohol. A little bit of flux and it then solders nicely. Plan ahead and drill before doing any soldering. Also note how the wire enters the slot from behind, then is bent over the top. Takes a lot of planning on how to fit all those ground wires.

Also, the S1 transformer wires are enamel coated solid core magnet wire. PL probably dipped the ends into a solder pot to burn off the enamel and tin the wire ends. If you change the length of them, scrape the enamel off with a Xacto blade or something similar before tinning them. It might take a couple scrapings and tinnings to get them correctly tinned BEFORE you solder them in place. A little flux also helps here, not much, just a little.

Also, the S1 transformer wires are enamel coated solid core magnet wire. PL probably dipped the ends into a solder pot to burn off the enamel and tin the wire ends. If you change the length of them, scrape the enamel off with a Xacto blade or something similar before tinning them. It might take a couple scrapings and tinnings to get them correctly tinned BEFORE you solder them in place. A little flux also helps here, not much, just a little.

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

i am truly honored....I added Costa Rica to the sold to country list on the website in honor of Gene...

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

MusicSteve

Journeyman

and

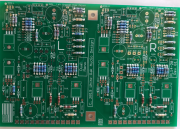

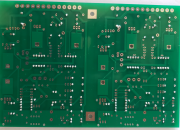

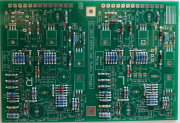

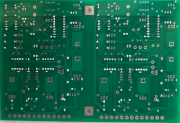

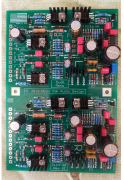

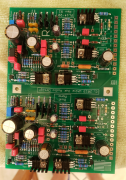

your missing some resistors

your missing some resistors

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

and

your missing some resistors

this version of the driver board....is built for full or quasi compliment....and some parts get installed under one config and vice versa....

this kit is labeled extremely well....and for me...does not assume too much nor assume too little...

assume is a word to get you in trouble....when and a** comes before u and me...

thanks for watchiing....the eyes have it!!!!

lol

keep watchin....

MusicSteve

Journeyman

which one are you doing?this version of the driver board....is built for full or quasi compliment....and some parts get installed under one config and vice versa....

this kit is labeled extremely well....and for me...does not assume too much nor assume too little...

assume is a word to get you in trouble....when and a** comes before u and me...

thanks for watchiing....the eyes have it!!!!

lol

keep watchin....

Full or comp?

MusicSteve

Journeyman

Gene

I see some diodes backwards,, check w sheet to find them

I see some diodes backwards,, check w sheet to find them

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

i already caught it and repaired....Gene

I see some diodes backwards,, check w sheet to find them

but, thank you so much for checking....

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

i did not see others....D12A, might be others.

but, i am tired....and will start fresh in the morning....

with a good ole fashion inspection!!!!

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...

which one are you doing?

Full or comp?

full comp....

gene french

Veteran and General Yakker

- Joined

- Mar 6, 2022

- Messages

- 5,888

- Tagline

- music...the healer of souls...