I asked Joe if the backplane thermal switches on the upcoming Model ONE are DC and indeed they are..

That prompted the question:

"Did you ever publish a Mod to change the 400 / 700 thermal switches to DC ?

Any particular scheme that would be beneficial ? "

I am curious to see who has gone down this path and to what success ?

A couple of us have jumped in on the Model ONE thread but I think it deserves to stay on track.

So, The thread is open for business......

Who's first ?

M

That prompted the question:

"Did you ever publish a Mod to change the 400 / 700 thermal switches to DC ?

Any particular scheme that would be beneficial ? "

I am curious to see who has gone down this path and to what success ?

A couple of us have jumped in on the Model ONE thread but I think it deserves to stay on track.

So, The thread is open for business......

Who's first ?

M

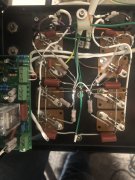

![IMG_5304[1].JPG](/data/attachments/76/76264-eb3adacafbaaa328a410eff529f8eff9.jpg)