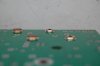

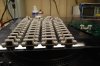

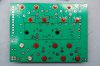

I had some free time on my hands and wanted to design something to hold the cool standoffs that Joe is using for his backplane design. So here's my first cut with a couple of fastener types. The fasteners I used are nylon so it won't hinder the heat transfer to the standoff and board. I only soldered in one set of standoffs as my wife wanted a barbeque tonight - but the pair of standoffs went in fine and no apparent issues with the nylon screws.

Attachments

-

78.9 KB Views: 78

-

96.3 KB Views: 78

-

78.2 KB Views: 67

-

85.9 KB Views: 75