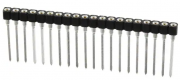

To make a long story short, you decide to replace a polarized cap with a bipolar one, which normally takes more space and if there is no enough space, would you consider use this:

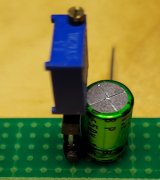

... to make something like this:

or something like this:

or just put a good quality polarized capacitor and move on.

Yeah, it probably looks crazy but sometimes you need to be creative.

Observe that lower plastic part is added by me as a support, to prevent a pressure to a pcb pads and solder joints.

... to make something like this:

or something like this:

or just put a good quality polarized capacitor and move on.

Yeah, it probably looks crazy but sometimes you need to be creative.

Observe that lower plastic part is added by me as a support, to prevent a pressure to a pcb pads and solder joints.