I have a 45 year old system that I've managed to continue to enjoy with one exception. The preamp continues to drop a channel at lower volumes - in all modes - can usually bring it back by increasing the volume dramatically. I've had both the power amp (300 Series 2)) and preamp serviced professionally (preamp twice) only to have the problem recur after a few months. I'm assuming this is caused by worn or dirty contacts in one of the obsolete front panel controls. I bought a can of DeoxIT D5 with the intent to clean and lubricate these controls, but am stumped by what I'm seeing. The pots (I think that's what you call them) on the Tone and Balance controls appear to be sealed, with no small openings like I see on others that would allow the cleaner to penetrate. The stepped volume control is a cube with multiple sections bolted together - it's labeled 9D4B 50K (then ohm symbol?) X2 Japan and what looks like Alrs in script. It looks like this has been resoldered to the board, so I'm thinking it has been disassembled and cleaned previously by someone that knew what they were doing. I will appreciate any thoughts as to what you think the most likely culprit is (volume control?) and whether this is something that I could service. I know little about electronics but would be totally comfortable desoldering the volume control from the board for disassembly and cleaning if that's the appropriate step to take. One last note - the techs that have serviced these units have never been able to replicate the problem of a dropped channel. When picking up the units after service I noticed they were using very small single driver speakers on their test benches. I'm driving a pair of Nestorovic Type 3s with dual woofers, midrange and ribbon tweets - wondering if the different load or impedance the amp is seeing explains it. Many thanks.

Another Phase Linear 3300 Series 2 Pre Amp

- Thread starter DougD

- Start date

- Joined

- Jan 14, 2011

- Messages

- 75,365

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

Deoxit D5 is used more for a rinse. Use D100 for initial cleaning.

A few times ive had to desolder and disassemble every forward facing switch or controlbutton on the faceplate. It can be done just got to be careful.

I didnt find the 3300 intimidating in any way, pretty straight forward, good luck young grasshopper. .

A few times ive had to desolder and disassemble every forward facing switch or controlbutton on the faceplate. It can be done just got to be careful.

I didnt find the 3300 intimidating in any way, pretty straight forward, good luck young grasshopper. .

- Joined

- Jan 14, 2011

- Messages

- 75,365

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

I have a 45 year old system that I've managed to continue to enjoy with one exception. The preamp continues to drop a channel at lower volumes - in all modes - can usually bring it back by increasing the volume dramatically. I've had both the power amp (300 Series 2)) and preamp serviced professionally (preamp twice) only to have the problem recur after a few months. I'm assuming this is caused by worn or dirty contacts in one of the obsolete front panel controls. I bought a can of DeoxIT D5 with the intent to clean and lubricate these controls, but am stumped by what I'm seeing. The pots (I think that's what you call them) on the Tone and Balance controls appear to be sealed, with no small openings like I see on others that would allow the cleaner to penetrate. The stepped volume control is a cube with multiple sections bolted together - it's labeled 9D4B 50K (then ohm symbol?) X2 Japan and what looks like Alrs in script. It looks like this has been resoldered to the board, so I'm thinking it has been disassembled and cleaned previously by someone that knew what they were doing. I will appreciate any thoughts as to what you think the most likely culprit is (volume control?) and whether this is something that I could service. I know little about electronics but would be totally comfortable desoldering the volume control from the board for disassembly and cleaning if that's the appropriate step to take. One last note - the techs that have serviced these units have never been able to replicate the problem of a dropped channel. When picking up the units after service I noticed they were using very small single driver speakers on their test benches. I'm driving a pair of Nestorovic Type 3s with dual woofers, midrange and ribbon tweets - wondering if the different load or impedance the amp is seeing explains it. Many thanks.

"Alps"

If you just spray it with D5, your scratchy/cutout issues will be back. Even with F5 it will come back. I use a touch of D100L and a touch of Fader Grease (Deoxit) too. That will cure pot issues for years. That shit aint cheap though. I paid $40 for the D100L but the bottle lasted 6-8 years and I use a 1/2 drop on all pots (After cleaning with D5/F5...........).

The ALPS potentiometers are probably some of the best in the audio world. Typically very accurate and reliable. I would reflow all the solder junctions related to the audio signal (volume pot, balance, tone controls, RCA jacks, etc.).

The fact that the problem occurs in only one channel points to a bad connection somewhere.

If the above work does not produce good results, then you can service the ALPS potentiometer or replace it if you can find one.

The fact that the problem occurs in only one channel points to a bad connection somewhere.

If the above work does not produce good results, then you can service the ALPS potentiometer or replace it if you can find one.

What a treat finding such a knowledge base willing to share - it's much appreciated. Hoping some additional detail will help pin down the source of the problem. The fact that two services have eliminated the problem - only to have it return - suggests something's being cleaned (inadequately) as WOPL Sniffer suggests. Operating all switches and pots repeatedly has no effect in bringing back the dropped channel, except the volume control. And with that I would expect simply rotating it would bring back the channel if this was the source of the problem, but it's only at very high or full gain that the channel pops back - thinking that suggests the problem is elsewhere? I'll start with the resolder since that's the least invasive, and hold off on cleaning the pots since they'll all have to be disassembled for cleaning and lubricating. I ordered an aerosol can of D100 (is that the same as D100L?), and will order some fader grease. Any/all of this is cheap if it means avoiding future servicing. Thanks again for any additional thoughts.

You should avoid regular D stuff in carbon comp pots. Stick to the F100 / F5 there. In some cases the D100 takes the trace right off the pot.

If you do manage to get it clean, silicone grease will keep it working well. Fader grease is rather pricey, and you should already own dielectric grease.

If you do manage to get it clean, silicone grease will keep it working well. Fader grease is rather pricey, and you should already own dielectric grease.

Good catch, I use the F100L (1/2 drop) and a touch of the FG-213 (fader grease) after cleaning with the D5/F5 sprays. There were so many D's and F's flying that I goofed up my numbers. I don't use the D100/D100L or any of the red stuff.

You don't need to disassemble the pots. A good flush with the sprays and let them sit for a few minutes and then you can use the grease/drops...... On a very RARE occasion, I have taken them apart but other than that, I have used this method for 10 years on the WOPL Pots and have not had to mess with them after that.

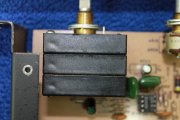

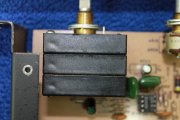

Thanks for clarifying the cleaners and lubes. The following pics are the bass and treble pots - don't see any type of opening that would allow entry.

This is the balance pot, where I do see holes at 3 and 9 o'clock along with slits around the circumference. And finally the volume pot with no openings but with bolted segments that would seem to allow for easy disassembly after desoldering from the board. Holler if I'm missing something, and thanks again everyone.

And finally the volume pot with no openings but with bolted segments that would seem to allow for easy disassembly after desoldering from the board. Holler if I'm missing something, and thanks again everyone.

This is the balance pot, where I do see holes at 3 and 9 o'clock along with slits around the circumference.

And finally the volume pot with no openings but with bolted segments that would seem to allow for easy disassembly after desoldering from the board. Holler if I'm missing something, and thanks again everyone.

And finally the volume pot with no openings but with bolted segments that would seem to allow for easy disassembly after desoldering from the board. Holler if I'm missing something, and thanks again everyone.

- Joined

- Jan 14, 2011

- Messages

- 75,365

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof