WOPL Sniffer

Veteran and General Yakker

Mark, as you mentioned, the 700B Inserts have a unpainted perimeter and the reason for this is the Silk-Screener has to be able to mount them in his machine which leaves the unpainted perimeter. Here is how to fix that.

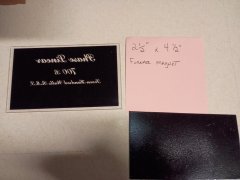

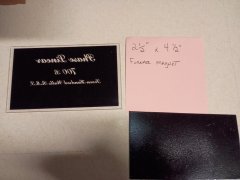

Get a piece of furnace magnet that all the home improvement stores sell. Trim a piece 4.5" x 2.5" which will make it just a smidge smaller than the unpainted perimeter.

Lay the insert face down on something clean, smooth and soft (Cardboard?) as these are silked from the back and that is where you will touch up the insert.

Place the magnet inside the painted portion

Fog with several LIGHT COATS of flat black ensuring you spray straight down so you don't get paint under the magnet. keep fogging LIGHTLY until the perimeter blends in.

Let it dry for the day and then you can use your Novus #2 fine scratch remover and buff out the front until it meets your specs. Take your time and go slow. if you overwork the insert with the buffer (I have a small 3" buffer), or you will kill the insert.

Tip 1. I have an old 700B face plate and I put some blue tape in the insert hole holding the insert from flying away because you can't hold it and buff it efficiently. Take 2 strips of blue painters tape, fold it to make your own double sided tape and put it in the face plate cutout. Use shitty tape and it will peel the paint off what you just fixed. Also this is why we let it dry for the day after painting it. If the paint isn't cured enough, wave bye-bye to your hard work and next time use a painters mask because you must have huffed too much Rustoleum and forgot common sense. Easy Peasy

a.

b.

c.

d.

I know some of you who have been buying these for your upgrades may have your own preferred way of doing it which is cool, some may have been scratching your head and just inserted it without painting but the Silk Screener is from Bama and you never know if your bezels will cover the unpainted portion so here is an idea you can follow. Sometimes there is a paper thin gap around the edge where the insert and the cutout is, I went under the scope and used some RTV and filled it in. Good luck guys.

Get a piece of furnace magnet that all the home improvement stores sell. Trim a piece 4.5" x 2.5" which will make it just a smidge smaller than the unpainted perimeter.

Lay the insert face down on something clean, smooth and soft (Cardboard?) as these are silked from the back and that is where you will touch up the insert.

Place the magnet inside the painted portion

Fog with several LIGHT COATS of flat black ensuring you spray straight down so you don't get paint under the magnet. keep fogging LIGHTLY until the perimeter blends in.

Let it dry for the day and then you can use your Novus #2 fine scratch remover and buff out the front until it meets your specs. Take your time and go slow. if you overwork the insert with the buffer (I have a small 3" buffer), or you will kill the insert.

Tip 1. I have an old 700B face plate and I put some blue tape in the insert hole holding the insert from flying away because you can't hold it and buff it efficiently. Take 2 strips of blue painters tape, fold it to make your own double sided tape and put it in the face plate cutout. Use shitty tape and it will peel the paint off what you just fixed. Also this is why we let it dry for the day after painting it. If the paint isn't cured enough, wave bye-bye to your hard work and next time use a painters mask because you must have huffed too much Rustoleum and forgot common sense. Easy Peasy

a.

b.

c.

d.

I know some of you who have been buying these for your upgrades may have your own preferred way of doing it which is cool, some may have been scratching your head and just inserted it without painting but the Silk Screener is from Bama and you never know if your bezels will cover the unpainted portion so here is an idea you can follow. Sometimes there is a paper thin gap around the edge where the insert and the cutout is, I went under the scope and used some RTV and filled it in. Good luck guys.