I have been experimenting with some easy modifications on the PL36 driver board. My main interest has been to modify the pre-driver and driver circuit to reduce crossover distortion that, in my opinion, has always been too high in the 400II and 700II amps.

Here is some history of my “test amp†(for those who are curious)… it is a 700B that had been raped and pillaged. Meters were mis-matched and do not work (still don't), no outputs or drivers, main caps were dented (punctured through to the inside) and screw threads were stripped, half of all the output transistor emitter resistors were burnt or missing, no rail fuse covers (main fuse cover intact), no driver board and some sockets damaged or not usable. However, the power transformer was in good shape as well as the chassis (in general). I bought it from a fellow Phase Linear tinkerer who had hopes of restoring it, but he knew it would never get the attention it needed, so I acquired it for next to nothing. I bought it with the intention of using it for testing different circuit modifications; hence it is my 700 test mule.

I replaced the main filter caps with 20kuF/100VDC types, new bridge rectifier and rewired the output section for full comp operation using MJ15204 and MJ15025’s. Front level pots are on the face, but not connected (on purpose). I am using an original PL36 PCB from a donor 400II.

Primary Modifications

Secondary Modifications

Performance

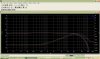

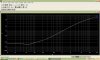

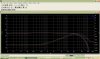

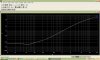

THD+N is reduced across the frequency band. At 1 Watt / 1kHz / 8 Ohm, distortion is < .01%. At 1 Watt / 20kHz / 8 Ohm, distortion is < 0.1%. At higher powers, the distortion across the band drops as well. Above 10 Watts (although not shown, I’ll have to post another graph) THD+N at 20kHz is well below < 0.09%, which is very good compared to a “stock PL36â€.

This is excellent performance and listening tests (my ears) confirm the changes are audible.

One drawback of this modification is that the idle temperature of the amp will go up slightly, but that’s the tradeoff.

View attachment Phase Linear 400II_700II_ New Output Design_Triple_DIY_v1.1_081517.pdf

See attached files for some tests I ran.

Here is some history of my “test amp†(for those who are curious)… it is a 700B that had been raped and pillaged. Meters were mis-matched and do not work (still don't), no outputs or drivers, main caps were dented (punctured through to the inside) and screw threads were stripped, half of all the output transistor emitter resistors were burnt or missing, no rail fuse covers (main fuse cover intact), no driver board and some sockets damaged or not usable. However, the power transformer was in good shape as well as the chassis (in general). I bought it from a fellow Phase Linear tinkerer who had hopes of restoring it, but he knew it would never get the attention it needed, so I acquired it for next to nothing. I bought it with the intention of using it for testing different circuit modifications; hence it is my 700 test mule.

I replaced the main filter caps with 20kuF/100VDC types, new bridge rectifier and rewired the output section for full comp operation using MJ15204 and MJ15025’s. Front level pots are on the face, but not connected (on purpose). I am using an original PL36 PCB from a donor 400II.

Primary Modifications

- Input filter – The input filter on the PL36 driver board is set to about 65kHz, -3dB roll off. This may or may not have been the design goal, but on the 400 and 700 series Two’s that I have, this is about the average upper frequency response. The original cap used is a ceramic 220pF type. These types of ceramic caps have a huge tolerance. If the cap was accurate, the roll off would be about 90kHz. Changing C112 to 68pF moves the low pass roll off to 300kHz. In most home amps, the input filter is set to around 300kHz. This is to ensure that RF interference is not (attempted) to be amplified. In PA use or other known noisy environments, an input filter set for a lower roll-off is beneficial.

- Most (modern) home amps that fall into the “Hi Fi†category have at least a 100kHz frequency response. Changing C106 to 100pF also helps extend the bandwidth just a bit in combination with item number 1 above. Extending the bandwidth to 100kHz does not imply that those extreme frequencies get amplified at full power. Extending the bandwidth helps ensure that 20kHz is not rolled off too much relative to the rest of the audio band.

- Pre-driver and driver circuit – The original circuit uses these stages in Class B operation. Re-configuring these devices for Class A operation reduces crossover distortion and other harmonics. In addition, the bias circuit is revised to accommodate the circuit changes.

- For these modifications, I am retaining the use of the LF351 op-amp.

Secondary Modifications

- Gain / Sensitivity – The original gain was too sensitive in my opinion, so I reduced it slightly. This helps improve the signal to noise ratio (especially at low listening levels). 1 Watt / 8 Ohm / 1kHz is 150mV. A 700 can still be driven to full power between 2 and 3VRMS. Any decent pre-amp can muster this.

- VAS – My PL36 driver board did not have the original steel heat sink 40412VI transistors, so I used a 2N3440 w/ large round heat sink. To reduce power dissipation, I reduced the VAS current from 10mA to 5mA. These VAS resistors values are also used in the original 700B. As a secondary test, I wanted to see if the slew rate of the amp was affected by reducing the VAS current, and in my tests, it does not appear to be affected (If it is, it is very slight). The 700 test mule put out full power at 20kHz. About 375 Watts, I could start to see 20kHz slewing. The large round heat sink would probably be OK with 10mA, but most home amps use between 5 and 10mA of VAS current anyway. By using a triple EF output stage, 5mA is plenty of drive for the amp stages anyway.

Performance

THD+N is reduced across the frequency band. At 1 Watt / 1kHz / 8 Ohm, distortion is < .01%. At 1 Watt / 20kHz / 8 Ohm, distortion is < 0.1%. At higher powers, the distortion across the band drops as well. Above 10 Watts (although not shown, I’ll have to post another graph) THD+N at 20kHz is well below < 0.09%, which is very good compared to a “stock PL36â€.

This is excellent performance and listening tests (my ears) confirm the changes are audible.

One drawback of this modification is that the idle temperature of the amp will go up slightly, but that’s the tradeoff.

View attachment Phase Linear 400II_700II_ New Output Design_Triple_DIY_v1.1_081517.pdf

See attached files for some tests I ran.

Last edited: