Dnspy007

Journeyman

I'm ready to start my WOPL 400 Series 2 project. I've read the Bom/build instructions several times now to familiarize myself on the order in which to proceed. (recommended by Joe) I would like to thank everyone for the detailed builds, Pictures, Comments and suggestions in their posts. Also, Mark Comer for his videos.(Enjoy watching, Very informative) I've learned several do's and don'ts, Things to check before installing(Correct parts, orientation etc...,The best time to install, to make an easier build.(Triple Check before welding) I can't claim to possess the skill level shown by the members here. I will greatly appreciate any Help and Suggestions. Hopefully, they will lead me to a better build. Again, Thanks guys....

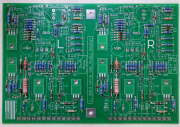

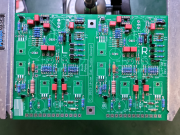

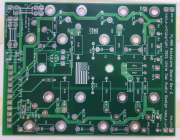

A few Before pictures....

A few Before pictures....