Been looking for a few new tools, mine have been around the world (seriously) and were really not the best but they lasted quite a while (Xcelite) and did a pretty good job. They are getting dull and were not made of the best materials. I see some pretty expensive stuff out there but are there any good tools for a decent price? Basically I'm looking for 4-5" flush cutters, nippers, round nose and bent nose pliers. I'm looking at a set of Baby Wubbers pliers (Pakistan) and they have all the pliers but not flush cutters or nippers. Any thoughts on hand tools (the small stuff for trons and soldering). Lindstroms are out of my league........... Sets would be cool... No hammers or vice grips please

Small Electronics Hand Tools

- Thread starter WOPL Sniffer

- Start date

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

Been looking for a few new tools, mine have been around the world (seriously) and were really not the best but they lasted quite a while (Xcelite) and did a pretty good job. They are getting dull and were not made of the best materials. I see some pretty expensive stuff out there but are there any good tools for a decent price? Basically I'm looking for 4-5" flush cutters, nippers, round nose and bent nose pliers. I'm looking at a set of Baby Wubbers pliers (Pakistan) and they have all the pliers but not flush cutters or nippers. Any thoughts on hand tools (the small stuff for trons and soldering). Lindstroms are out of my league........... Sets would be cool... No hammers or vice grips please

I have upgraded everything I had to Klein pliers and strippers, Wiha screw and Torx drivers, Xcelite nut drivers

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

I hadn't heard of Wiha for hand drivers until a few months back. I recently purchased a full set of Flats & Phillips after first buying a big set of Torx that I needed for work & home.

Wiha's are solidly built and I can see them being something I pass down to my kid. They weren't cheap but not as expensive as Snap-On. The handle grips on all of them are top shelf.

Wiha's are solidly built and I can see them being something I pass down to my kid. They weren't cheap but not as expensive as Snap-On. The handle grips on all of them are top shelf.

Gotta go with Joe on this, Wiha screwdrivers, Snap-On for the BIG screwdrivers, Heinz57 nut drivers, Mini side cuts and needle nose--Solingen (German), Strippers and crimpers---Kleins BABY!!

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

Jani bought me a complete set of LARGE Wiha 1000 volt insulated screwdrivers for work, the grips are THE SHIT!! High quality tips on those, very hard to distort the tips...

I'm hard on Torx tips. Can't tell you how many sets of chinese craptastic Torx drivers I've blown through over the years, but these Wiha ones are standing strong.

Haven't damaged one yet.

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

A company called Xuron might have what you need. Well stocked hobby shops should be able to get them. And they're made in USA.

https://www.walthers.com/xuron-corp.

https://www.walthers.com/xuron-corp.

Last edited:

Well, I picked up my first set of tools for soldering and wiring amps. It was a set of 4 ( chain-nose / round-nose / flat-nose / curved chain-nose, all stainless steel). Used them all week and I love them. The handles are a soft foam and these are less than 5" from tip to tip. Great for the small shit I do all day (yes, I do other things besides drink beer)... They were under 20 bucks per tool and they should last a good long time. They got a funny ass name but they were NOT MADE IN CINA.... (More like Pakistan).

http://www.wubbers.com/baby.htm

Now I'm waiting on my cutter set. I needed to replace my 20+ year old stuff I cobbed from the NAV, The jaws were getting dull and had a bit of corrosion (from drooling I'm sure) so they were not cutting it (pun intended). Picking out small profile cutters took me a week to sort through the flush cut, micro bevel, oval head semi flush micro beveled blah blah blah but I settled on the second Tier Lindsrom cutters. I could not afford the $60 each cutters so I went to the next level down. The others were ESD Ergonomic, Carpel Tunnelonic, Ionic sonic electronic and I didn't need all that. Plus, they double as a beer can opener. I'll give these a shakedown in the next couple days. When I sell an amp, I try to buy something for the bench to make my job easier (along with some spare parts for a build or two).

LINDSTROM® 8150 CUTTERS DIAGONAL CUTTERS - OVAL HEAD - MICRO-BEVEL CUTTING EDGE

About $25

LINDSTROM® 8160 CUTTER PRECISION MICRO-BEVEL CUTTER 80-SERIES OVAL HEAD PLIERS

About $25

LINDSTROM 8140 DIAGONAL PRECISION CUTTER 80-SERIES OVAL HEAD MICRO-BEVEL PLIERS

About $25

I had already snagged some nice screwdrivers a year or 2 ago and I like them a lot. They are Wago and are comfortable and sturdy. I got 2 sets of 3 for nothing (worth about $50). They work great for the amps but I could use some Phillips tips to match.

http://www.wubbers.com/baby.htm

Now I'm waiting on my cutter set. I needed to replace my 20+ year old stuff I cobbed from the NAV, The jaws were getting dull and had a bit of corrosion (from drooling I'm sure) so they were not cutting it (pun intended). Picking out small profile cutters took me a week to sort through the flush cut, micro bevel, oval head semi flush micro beveled blah blah blah but I settled on the second Tier Lindsrom cutters. I could not afford the $60 each cutters so I went to the next level down. The others were ESD Ergonomic, Carpel Tunnelonic, Ionic sonic electronic and I didn't need all that. Plus, they double as a beer can opener. I'll give these a shakedown in the next couple days. When I sell an amp, I try to buy something for the bench to make my job easier (along with some spare parts for a build or two).

LINDSTROM® 8150 CUTTERS DIAGONAL CUTTERS - OVAL HEAD - MICRO-BEVEL CUTTING EDGE

About $25

LINDSTROM® 8160 CUTTER PRECISION MICRO-BEVEL CUTTER 80-SERIES OVAL HEAD PLIERS

About $25

LINDSTROM 8140 DIAGONAL PRECISION CUTTER 80-SERIES OVAL HEAD MICRO-BEVEL PLIERS

About $25

I had already snagged some nice screwdrivers a year or 2 ago and I like them a lot. They are Wago and are comfortable and sturdy. I got 2 sets of 3 for nothing (worth about $50). They work great for the amps but I could use some Phillips tips to match.

Attachments

-

75.6 KB Views: 17

I saw this video on Youtube this morning and the soldering tool beats a lot of what we've seen out there. I love the idea of its heavy steel base. On the Amazon link there's also a model designed to mount up with a standard Panavise base!

There's a few other cool gadgets too. The guys a bit of a dweeb but the gadgets are cool.

Youtube link (dweeb):

https://www.youtube.com/watch?v=gKGjxq96m-o&t=382s

Dweeb's Amazon link for tool:

https://www.amazon.com/s/ref=nb_sb_...ping+Hands&rh=i:aps,k:Quadhands+Helping+Hands

MLTOOLS link for helping hands:

http://www.mltools.com/mltools-helping-hands-soldering-tool-with-sturdy-steel-base-vs339

There's a few other cool gadgets too. The guys a bit of a dweeb but the gadgets are cool.

Youtube link (dweeb):

https://www.youtube.com/watch?v=gKGjxq96m-o&t=382s

Dweeb's Amazon link for tool:

https://www.amazon.com/s/ref=nb_sb_...ping+Hands&rh=i:aps,k:Quadhands+Helping+Hands

MLTOOLS link for helping hands:

http://www.mltools.com/mltools-helping-hands-soldering-tool-with-sturdy-steel-base-vs339

- Joined

- Nov 15, 2021

- Messages

- 482

- Location

- near Liverpool, NY

- Tagline

- Lifelong student / listening = bliss

My penchant for old gear always seems to lead me to a Mexican standoff with an old nemesis...in the form of one (or more) stuck Phillips screws...

For what it's worth, here's a short list of cheats/hacks/tips I've collected over the years -- hopefully one or more of the following will help lower your frustration level while working on this stuff --

1) You're doing a field repair, and all you got is your backup set of tools with you. They aren't worn out, but not the good stuff back in the shop. Meanwhile, most of the phillips screws came out, but there's the last couple that are just begging to strip out at the slightest slip.

The solution? Use this stuff to increase the grip between tool tip & screw head:

A little dab will do ya. Cheap, and a 3 oz tube takes up almost no room in your toolbox.

(NOTE: This works with a normal screwdriver and/or an impact screwdriver. Really saved my bacon on numerous occasions.)

****

If you read about the history of the phillips screws, they are actually designed to 'cam-out' to avoid over-torquing during assembly. Of course, this does us no good when faced with one or more screws frozen in place for years. To help overcome this design feature when you really need to remove instead of destroy a fastener, make sure you have on hand one of the anti-camout bits:

The ridges provide 'bite'.

And for the fully-manual folks out there, here's a good example of a screwdriver that comes with the anti-camout feature:

FWIW, sometimes I've combined the valve grind compound + anti-camout bits for the really stubborn stuff.

Last but not least, while digging through old Electronics magazines for info on vintage test equipment, I happened across an ad illustrating the virtues of switching from slotted to phillips fasteners in your manufacturing process:

(Late '40s tip of the hat to NavLinear.)

I, for one, will never again look at phillips screws in quite the same way.

:0)

3D

For what it's worth, here's a short list of cheats/hacks/tips I've collected over the years -- hopefully one or more of the following will help lower your frustration level while working on this stuff --

1) You're doing a field repair, and all you got is your backup set of tools with you. They aren't worn out, but not the good stuff back in the shop. Meanwhile, most of the phillips screws came out, but there's the last couple that are just begging to strip out at the slightest slip.

The solution? Use this stuff to increase the grip between tool tip & screw head:

A little dab will do ya. Cheap, and a 3 oz tube takes up almost no room in your toolbox.

(NOTE: This works with a normal screwdriver and/or an impact screwdriver. Really saved my bacon on numerous occasions.)

****

If you read about the history of the phillips screws, they are actually designed to 'cam-out' to avoid over-torquing during assembly. Of course, this does us no good when faced with one or more screws frozen in place for years. To help overcome this design feature when you really need to remove instead of destroy a fastener, make sure you have on hand one of the anti-camout bits:

The ridges provide 'bite'.

And for the fully-manual folks out there, here's a good example of a screwdriver that comes with the anti-camout feature:

FWIW, sometimes I've combined the valve grind compound + anti-camout bits for the really stubborn stuff.

Last but not least, while digging through old Electronics magazines for info on vintage test equipment, I happened across an ad illustrating the virtues of switching from slotted to phillips fasteners in your manufacturing process:

(Late '40s tip of the hat to NavLinear.)

I, for one, will never again look at phillips screws in quite the same way.

:0)

3D

Last edited:

- Joined

- Nov 15, 2021

- Messages

- 482

- Location

- near Liverpool, NY

- Tagline

- Lifelong student / listening = bliss

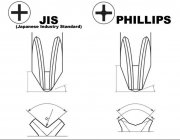

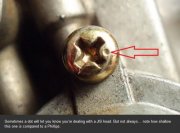

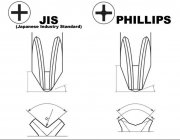

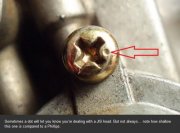

And just when you thought that things couldn't be made any more unfair, you end up having worse-than-usual luck while working on cars and electronics where the 'phillips' screws just don't seem to fit quite right. As it turns out, it's not a metric-vs-standard thing, it's because you are trying to loosen JIS fasteners with a phillips screwdriver. (!)

And here's a quick article with some additional detail:

https://www.motorcycle.com/ask-mo-anything/difference-between-japanese-jis-phillips.html

Hopefully these 2 posts will give you a quality excuse to add a few more tools to the toolbox.

(Why should Spence have all the fun? :0)

3D

And here's a quick article with some additional detail:

https://www.motorcycle.com/ask-mo-anything/difference-between-japanese-jis-phillips.html

Hopefully these 2 posts will give you a quality excuse to add a few more tools to the toolbox.

(Why should Spence have all the fun? :0)

3D

Last edited:

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof

- Joined

- Nov 15, 2021

- Messages

- 482

- Location

- near Liverpool, NY

- Tagline

- Lifelong student / listening = bliss

Lee,

Not so much electronics, but older/neglected Japanese vehicles equipped with the JIS fasteners were the bane of my motorhead existence. You have to really study the picture, but essentially the Phillips bit is too skinny/too tall to interface correctly with the JIS screw. You start to put any torque to it, and the screwdriver turns into a drill bit, neatly augering out the center of the screw. (This used to happen to me all the time - I hated that!)

Most of the time the JIS-equipped electronics (that's been kept dry/inside) comes right apart with normal phillips screwdrivers, but even then with the right tools it's still less fiddly (ie: less drop-sies) during disassembly/assembly thanks to the better fit.

But when working on a high-mileage Honda you can really tell the difference on every outing -- especially the high torque stuff like replacing the driver's door latch mechanism on a 30-year-old Civic.

3D

Not so much electronics, but older/neglected Japanese vehicles equipped with the JIS fasteners were the bane of my motorhead existence. You have to really study the picture, but essentially the Phillips bit is too skinny/too tall to interface correctly with the JIS screw. You start to put any torque to it, and the screwdriver turns into a drill bit, neatly augering out the center of the screw. (This used to happen to me all the time - I hated that!)

Most of the time the JIS-equipped electronics (that's been kept dry/inside) comes right apart with normal phillips screwdrivers, but even then with the right tools it's still less fiddly (ie: less drop-sies) during disassembly/assembly thanks to the better fit.

But when working on a high-mileage Honda you can really tell the difference on every outing -- especially the high torque stuff like replacing the driver's door latch mechanism on a 30-year-old Civic.

3D

Last edited:

- Joined

- Jan 14, 2011

- Messages

- 74,244

- Location

- Gillette, Wyo.

- Tagline

- Halfbiass...Electron Herder and Backass Woof