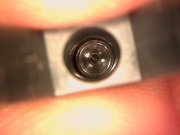

ABEC ratings are important on low tolerance devices, such as a tonearm. Designed for machining spindles, the ABEC 7 is really tight. But, there is also the exotic ABEC 9 available for some sizes.

Needless to say, ABEC 9 bearings can easily cost 100 times what an ABEC 1 bearing costs. Components are hand-matched based on exact sizing, and that costs money...

- ABEC 1: 0.0075 mm (0.000295″)

- ABEC 3: 0.0050 mm (0.000197″)

- ABEC 5: 0.0035 mm (0.000138″)

- ABEC 7: 0.0025 mm (0.000098″)

- ABEC 9: 0.0012 mm (0.000047″)

Needless to say, ABEC 9 bearings can easily cost 100 times what an ABEC 1 bearing costs. Components are hand-matched based on exact sizing, and that costs money...